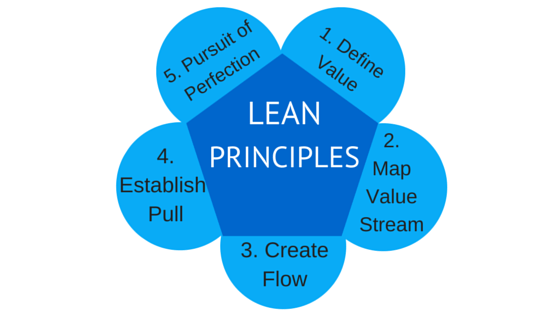

LEAN PRINCIPLES

Lean principles are at the core of how APPRO and CERRON work together to streamline processes, while keeping our customers’ best interests paramount in all we do. According to the Lean Enterprise Institute, “The core idea [of lean] is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources.”

The team at APPRO and CERRON originally implemented lean principles into our organizational processes in 2006. Since that time, our team continually works to make improvements in all we do. We have united these principles with our mission statement in our passionate pursuit of not only meeting our clients’ expectations, but exceeding them.

Lean Example #1 - Competitive Bidding

Challenge: In order for our clients to make an informed decision regarding a new commercial construction project, they need to have facts and figures in a timely manner.

Solution: Our team created a streamlined bid process, in which we efficiently turn around an accurate, competitive bid request in less time. We created a standardized bid sheet and proposal format. Additionally, we created a list of pre-screened vendors and subcontractors, who comply with our strict safety compliance and insurance requirements.

Benefit to our Customer: The benefit to our client is that we provide a precise bid in shorter time.

Lean Example #1 - Competitive Bidding

Challenge: In order for our clients to make an informed decision regarding a new commercial construction project, they need to have facts and figures in a timely manner.

Solution: Our team created a streamlined bid process, in which we efficiently turn around an accurate, competitive bid request in less time. We created a standardized bid sheet and proposal format. Additionally, we created a list of pre-screened vendors and subcontractors, who comply with our strict safety compliance and insurance requirements.

Benefit to our Customer: The benefit to our client is that we provide a precise bid in shorter time.

Ready to contact our team?

We can discuss your company's needs and how we might partner together, utilizing our Lean Process to create value for your next project.